Protecting tools from rust and corrosion would seem to be a

given for any tool manufacturer. Unfortunately, nothing could be

further from the truth. Because this essential step also adds to

manufacturing cost, many other hex tool manufacturers, with the

exception of Bondhus, cut corners by providing inadequate

protection.

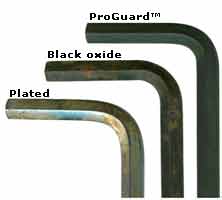

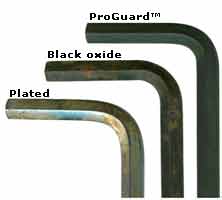

Tool manufacturers

deal with the problem of rust and corrosion by providing a range of solutions:

|

|

Protection considerations:

- Bondhus ProGuard™ dry surface finish is the most effective

solution available.

- Plating provides a degree of protection, but eventually nicks,

flakes or wears off, and allows water to seep in. At that point,

the tool is left unprotected.

- Black oxide finishes provide only limited protection. Almost

with the first use, the finish begins to wear off and allow

water to penetrate through to the tool.

- Coating a tool with oil, or no protection at all, leaves the

tool totally vulnerable to rust and corrosion.

|

Bondhus advantages:

- Conventional solutions to the problem of rust and corrosion fall

far short of even an adequate solution. None of these approaches provide the

degree of corrosion resistance suitable for the professional tool market.

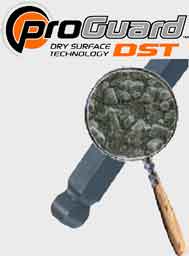

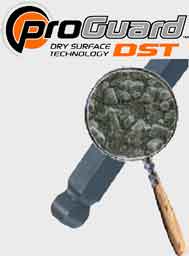

- The ProGuard™ technology developed by Bondhus offers a level of

protection that is vastly superior to any other solution

available. The combination of a small, tight grained crystal

structure and a dry to the touch oil create a surface that is

very difficult for moisture and contaminants to penetrate.

- ProGuard™ dry surface finish is a radically different

solution. It starts with caustic cleaning to remove all oxides

and impurities on the surface, and then uses a proprietary

electrolytic process to grow a very tight and small grained

crystal structure on the surface of the tool. In addition, a

fast drying oil is used to provide yet a second line of

protection.

- Line operators responsible for the ProGuard™ process receive

special training at Bondhus. The end result is Bondhus tools are

clean and dry to handle, maintain an attractive appearance, and

have the highest level of protection in the industry from rust,

corrosion, and the inevitable damage associated with a

deteriorating surface.

|

|

Resistance to salt-spray testing:

The results of comparative Salt Spray performance testing,

conducted by an independent lab on 5/16" hex wrenches, provide dramatic proof that the

Bondhus ProGuard™ corrosion protection is superior to any other

solution available.

Test method: The test was conducted in accordance with

ASTM:B117-94. The samples were tested as received with no

cleaning prior to exposure. The wrenches were supported at an

angle of 15° from vertical for 20 hours under controlled

conditions:

|

|

RESULTS: |

|

|

|