|

Customized

heat treating is key to the Bondhus line of hex tools achieving

the highest strength/hardness/ductility ratios in the industry.

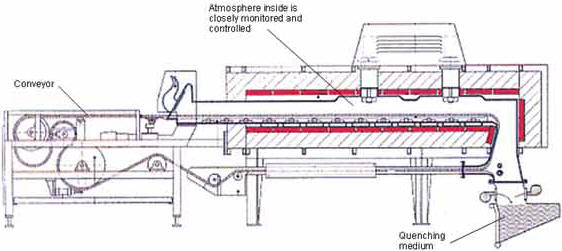

Bondhus uses what are known as ‘controlled atmosphere furnaces’

to monitor and maintain ideal levels inside the furnace.

Although they contribute to a higher cost of manufacturing,

these furnaces control problems such as carburization, decarb,

oxidation, and many problems experienced by the lower cost

processes used by other manufacturers. Customized

heat treating is key to the Bondhus line of hex tools achieving

the highest strength/hardness/ductility ratios in the industry.

Bondhus uses what are known as ‘controlled atmosphere furnaces’

to monitor and maintain ideal levels inside the furnace.

Although they contribute to a higher cost of manufacturing,

these furnaces control problems such as carburization, decarb,

oxidation, and many problems experienced by the lower cost

processes used by other manufacturers.

Bondhus controls the heat treating process by customizing it to

each individual tool size and the unique characteristics of

every batch of steel. In addition, Bondhus heat treating

personnel are specially trained and have many years of

specialized experience.

Anyone with a piece of steel and a torch can do a level of heat

treating. Attaining results that push the envelope beyond

industry accepted limitations requires equipment, skills, and

the years of research and development that Bondhus alone has

committed to their heat treating process.

|

Customized

heat treating is key to the Bondhus line of hex tools achieving

the highest strength/hardness/ductility ratios in the industry.

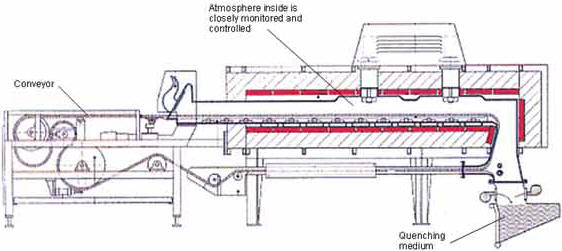

Bondhus uses what are known as ‘controlled atmosphere furnaces’

to monitor and maintain ideal levels inside the furnace.

Although they contribute to a higher cost of manufacturing,

these furnaces control problems such as carburization, decarb,

oxidation, and many problems experienced by the lower cost

processes used by other manufacturers.

Customized

heat treating is key to the Bondhus line of hex tools achieving

the highest strength/hardness/ductility ratios in the industry.

Bondhus uses what are known as ‘controlled atmosphere furnaces’

to monitor and maintain ideal levels inside the furnace.

Although they contribute to a higher cost of manufacturing,

these furnaces control problems such as carburization, decarb,

oxidation, and many problems experienced by the lower cost

processes used by other manufacturers.